HUNTSVILLE, Ala. — The U.S. Army opened the doors of a one-stop shop for development and integration of directed-energy capabilities at Redstone Arsenal in Huntsville, Alabama, last week as the Space and Missile Defense Symposium kicked off in the same town.

The Directed Energy Systems Integration Laboratory, or DESIL, will help speed up and streamline laser weapons research and development as the Army seeks to incorporate the technology into combat systems.

Simulation, component and subsystem testing, and verification and validation of overall systems can all take place in one lab at a single location, Lt. Gen. Dan Karbler, the head of the Army’s Space and Missile Defense Command, told Defense News in an interview at the symposium. The lab’s capabilities will help reduce technical and schedule risk for programs.

But it’s not just a lab: Beyond two huge garage doors is a 400-meter outdoor range with an enormous mound of earth at one end that will serve as a test range. The mound serves as a backstop to absorb the laser energy in testing.

Karbler, who previously led Army Test and Evaluation Command, said labs like DESIL will help shorten the process of evaluating, developing and testing new capabilities before fielding.

“I just go right out, I test it, and then I get to analyze the results right away and fix it right away versus going out to the range, maybe doing something, but then I have to bring it all back or ship all the [hardware] back. And then I own the range time,” Karbler said. “So it’s going to be a much tighter circle, tighter timeline, from concept, subcomponent, component system testing, analysis, regression analysis to retesting if needed.”

The Army is outfitting its Stryker combat vehicle with a 50-kilowatt laser for short-range air defense, and it is scaling up laser capability to deliver a 300-kilowatt laser on heavy trucks as part of its Indirect Fires Protection Capability that will use a variety of effects to neutralize drones, cruise missiles, rockets, artillery and mortar threats.

The service also recently announced it would work to put a 20-kilowatt laser on a small Infantry Squad Vehicle to defeat small drone threats on the move.

Many of the industry members helping the Army with these efforts are based in the Huntsville area, including Lockheed Martin and Leidos-owned Dynetics. The Army’s Rapid Capabilities and Critical Technologies Office, which focuses on directed-energy development, is also based in town.

The new lab will serve as the place where all future laser weapon technology experiments can “become reality,” Nicole Olbricht, chief of the systems integration division under Space and Missile Defense Command’s Technical Center, told Defense News during a tour of the facility.

“Huntsville is kind of the center for the Army right now for this,” Olbricht said. “So we’re essentially co-located with the customers, with the developers, the testers, with the integrators.”

Redstone will be the home for project offices like those of the Directed Energy-Short Range Air Defense system and the IFPC program currently in development.

The laser analysis team will also share space with the lab. The Army was breaking ground on the next-door facility while Defense News toured the DESIL digs.

“Prior to firing the laser downrange, the laboratory engineers will be able to define the quality of the laser system beam” by firing a laser into an instrumentation system, capturing data and evaluating results, Olbricht explained. Then the laser can be fired downrange and the results compared, she added.

The laboratory will serve as a key location to conduct modeling and simulation to support how laser systems might perform in battlefield scenarios and against a variety of threats.

Some of the capabilities that allow for indoor laser testing include the Robust Electric Laser Initiative that is capable of multi-kilowatt firing and helps prepare the lab to ensure laser instrumentation is ready.

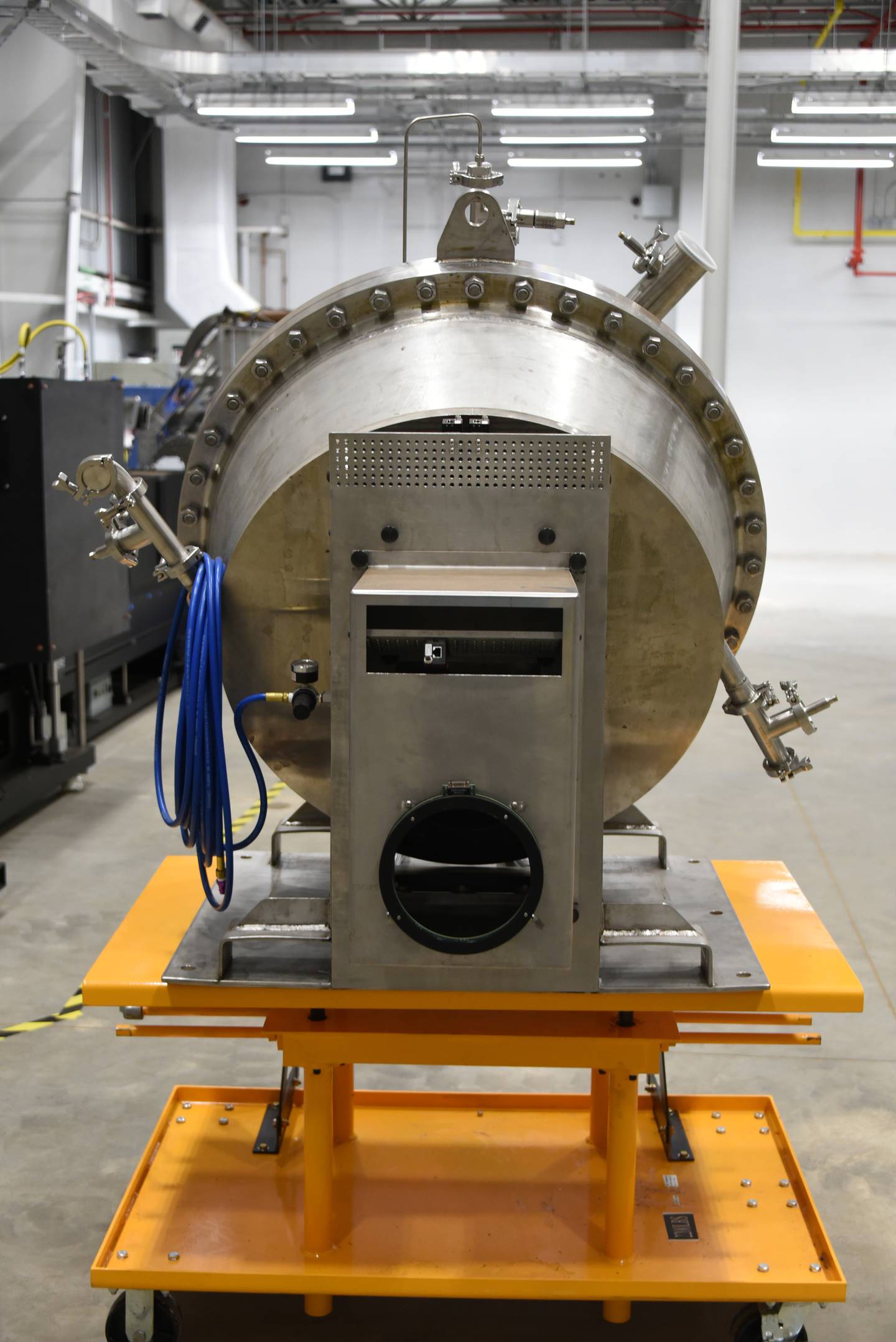

The Army’s lab also houses a system called SMASH — or Small Measurement and Analysis System for High-energy laser systems. “SMASH measures the thermal properties and optics effects after the laser is fired for a short period of time,” Olbricht said. “From the results delivered from the shot profile, SMASH analysis can create a basis of beam quality.”

Another key piece of equipment in the lab is the High Power Laser Beam Dump, which absorbs “extremely high amounts of energy for a long period of time,” Olbricht said.

The system includes components capable of circulating 120 gallons of water per minute. The water is heated through the laser firing process and returns to a water tank through a closed-loop system that cools the water and purifies it through reverse osmosis. Impurities in the water can “lead to catastrophic events for the system during laser tests,” Olbricht explained.

The lab was constructed as a minor military construction project, costing less than $6 million to build, an Army spokesperson told Defense News.

The lab will be sustained “on a reimbursable basis in that the Directed Energy programs and related organizations pay a small reimbursable use fee to utilize the capabilities when required,” the spokesperson added.

Jen Judson is an award-winning journalist covering land warfare for Defense News. She has also worked for Politico and Inside Defense. She holds a Master of Science degree in journalism from Boston University and a Bachelor of Arts degree from Kenyon College.